Collaboration resolves the supply problem

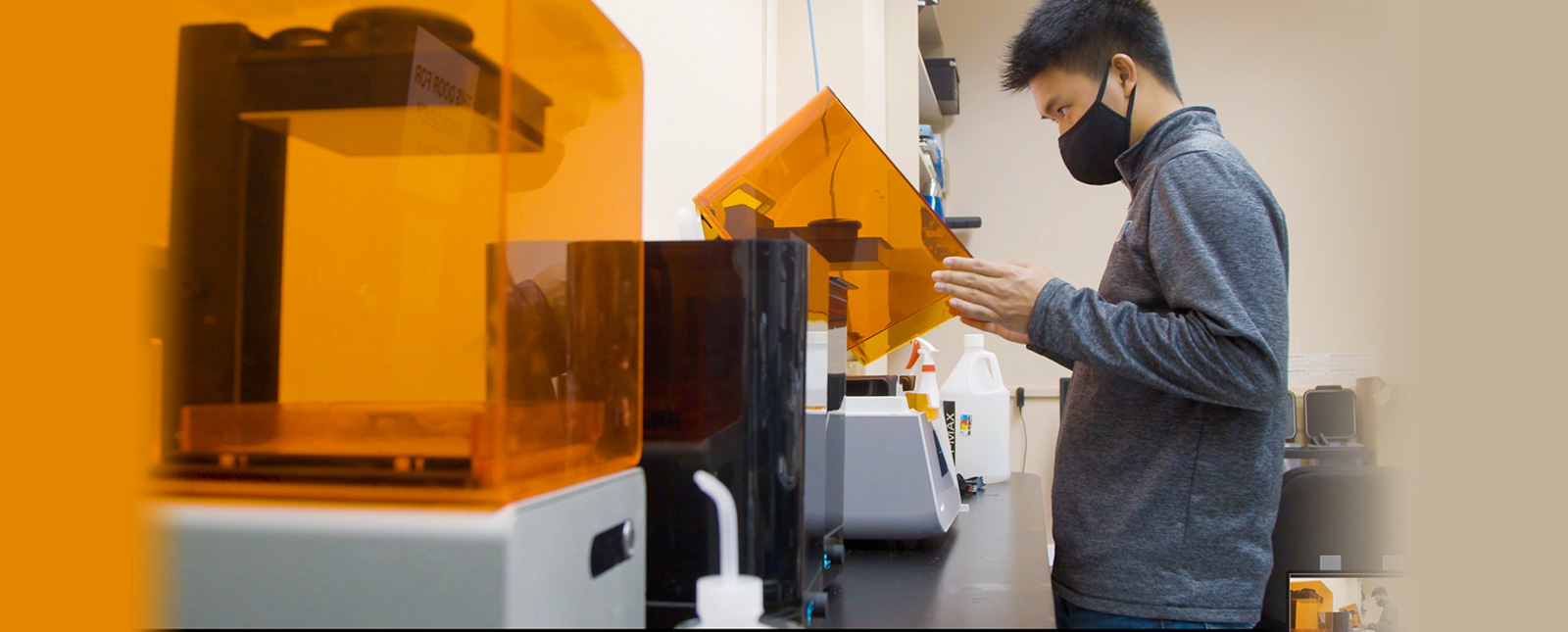

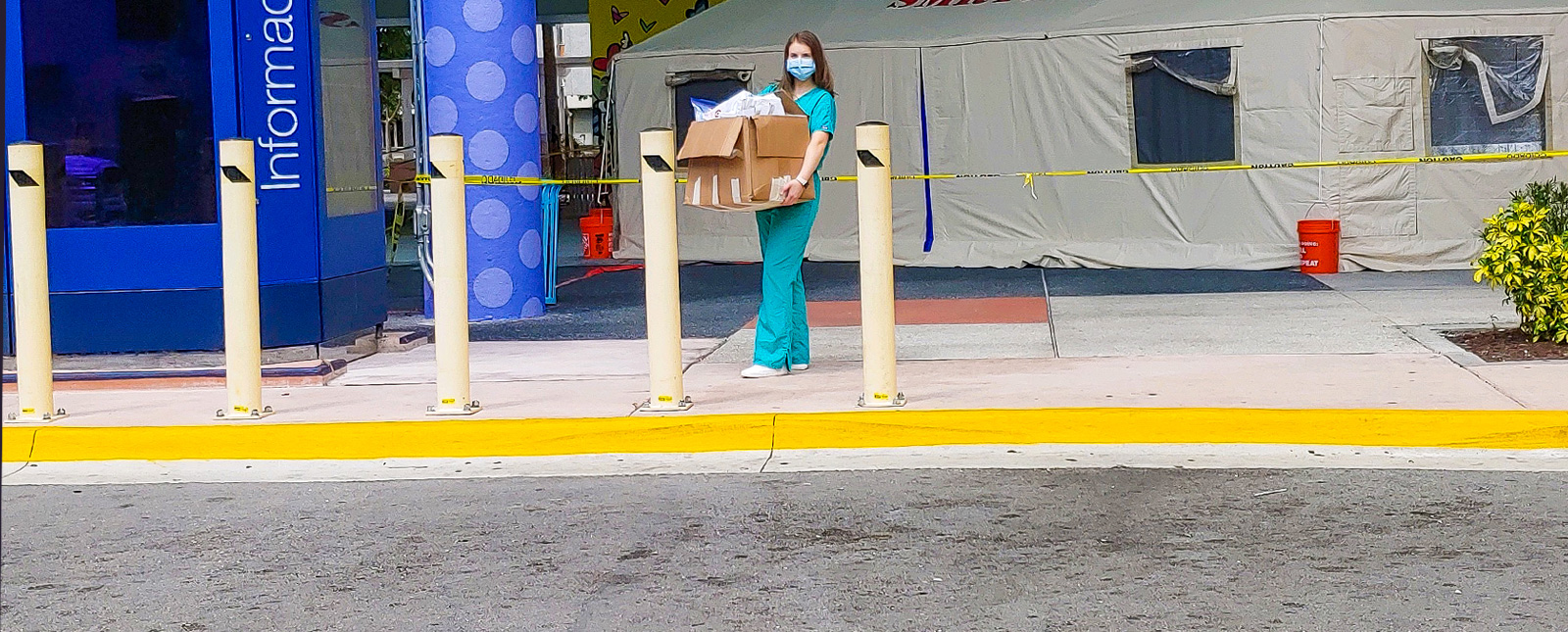

Biomedical engineers and architects at the University of Miami 3D-printed 1,000 nasopharyngeal swabs a day this past year, doing their part to help maintain the stockpile of these crucial tools that are being used by the tens of thousands at hospitals, community health clinics, and drive-through test sites each week. The six-inch-long, skinny, flexible plastic stick, which is inserted into the nasal cavity, remains the primary diagnostic tool used to test for COVID-19.

The team, including James Lai, who completed a biomedical engineering degree at the University in May and is currently in his first year of medical school at the Miller School of Medicine, pivoted its strategy in the fall after not receiving FDA approval for its initial design. Working with University and health system administrators and faculty members, Lai secured an FDA-approved design license that enabled the University to print much-needed nasopharyngeal swabs in-house—648 swabs every 11 hours. “The supply chain was thankfully restored. But it was still a huge collaboration, and we now have the ability to print swabs, if need be,” said Lai. “I felt empowered that the University and my professor took me seriously and provided the support I needed to do this project,” he noted.